Implementing a Warehouse Management System (WMS) is often a complicated endeavour with many questions surrounding the ROI. A best-in-class WMS will have a drastic impact on the management and optimisation of many processes across warehousing and distribution centres, as well as more intangible areas such as customer satisfaction, making it notoriously difficult to calculate the precise value added.

While there are hundreds of individual operations and processes that can be improved with a WMS, we’ve summarised some of the top areas that organisations see the greatest benefits from after implementing a solution.

Inventory Management & Optimisation

Effectively managing inventory levels at all times can be a challenging task, walking a fine line between ensuring enough stock is available for order fulfilment when needed, but not so much that the business ends up with a huge amount of capital tied up in idle inventory.

A WMS will provide visibility into real-time stock levels, enabling companies to gain the inventory and warehouse accuracy needed to reduce safety stock and optimise inventory levels. These benefits can subsequently be leveraged to optimise the purchasing cycle by avoiding buying stock until needed, facilitating Just-in-Time approaches, enabling organisations to take advantage of bulk order discounts, consolidate orders to vendors and reduce inbound shipments and associated costs.

Space Management

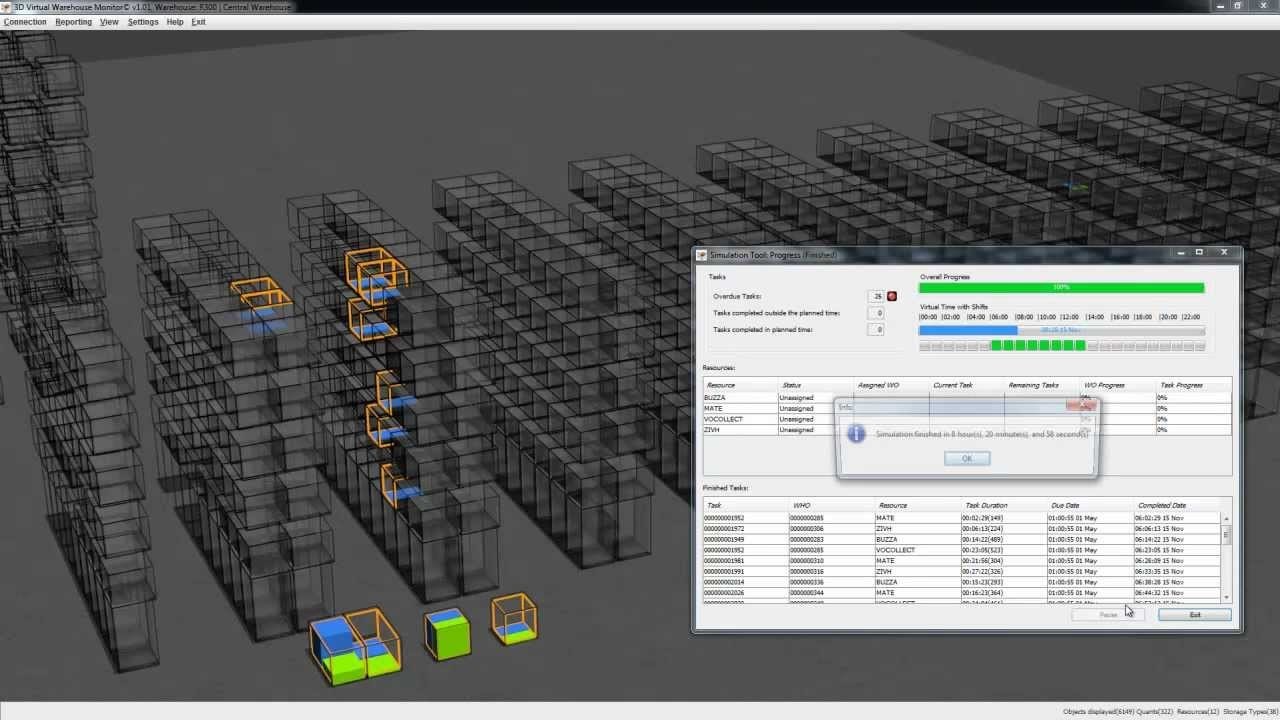

The efficient flow of people and goods throughout the warehouse is reliant on effective utilisation and management of space. Visualising, creating and managing an effective warehouse layout can be tricky, but a best-of-breed WMS can make this process a breeze.

Warehouse processes can be streamlined by utilising a WMS that makes defining storage areas and bin locations simple, as well as managing product storage using predefined rules based on the pre-set outlay. Detailed warehouse and material flow modelling optimises mechanised goods movement and control, in addition to increasing labour efficiency through reduced movement during picking cycles. This in turn will reduce maintenance costs of equipment and extend their lifespan, as well as increasing workforce productivity.

Labour Management

Labour can count for as much as 60% of the total cost of warehouse operations, making it vital for businesses to ensure productivity can be maximised across a flexible and easily scalable workforce.

With a WMS, organisations can use pre-routing systems to maximise efficiency of movement, slotting techniques to ensure better pick accuracy and more efficient replenishment, with detailed performance tracking to help optimise the workforce. Training cycles for new staff can be shortened, making it easier to scale the workforce to absorb business growth and increased volume with existing resources, all helping to maximise production levels while minimising costs.

Customer Satisfaction

Good customer service is obviously essential for success, but can be difficult to manage and constantly improve with the reliance on so many moving parts. Collaboration with the wider supply chain network is critical for optimising goods movement, but visibility between partners can be hard to achieve.

In order to effectively manage SLAs and avoid the penalties often imposed on distributors for breaching them, a WMS will help to improve shipping visibility and accuracy through the reduction of short ships, shipping errors and missed deliveries. Inventory transparency can also be enabled across the wider supply chain network, aiding collaboration with external partners.

Leading-Edge Technology Integration

Supply chains are constantly evolving as new technological capabilities arise, so to remain competitive businesses must ensure that systems and processes are agile enough to incorporate the best new solutions.

By integrating technologies such as IoT-enabled devices and machinery, cloud computing, advanced analytics and robotics, WMS capabilities can be expanded to enable the simplified management of highly automated warehouses. With the power to essentially bolt-on new technologies as the business becomes ready to use them, a WMS further increases the ROI of each individual solution added and vice-versa.

Enhancing these five aspects of supply chain management can provide ROI in as little as three to six months in some cases, but can go on to provide additional value for years to come. While this list is by no means exhaustive, the areas highlighted are key places to start when building the business case for implementing a WMS.