For many of us, the notion of Artificial Intelligence (AI) is something straight out of the realms of science fiction. The portrayal of AI in books and films has often been negative, creating a sense of worry and paranoia over the impacts to our lives and the changes that could result as a consequence. Independent thought that is outside the control of humans, especially when linked with the ability to take decisive actions based solely on computer interpretation, has been suggested as being responsible for everything from the gradual decline of human intelligence to the outright destruction of civilisation as we know it.

Yes, the idea of a “Skynet-esque” intelligence is more than a little far-fetched and may seem a little extreme in this context, but bear with me…

There is a perhaps overlooked side to the portrayal of AI within the Terminator franchise though. Consider some of the scenes that depict the manufacturing plants and the creation of the robots that are the focal point of the films – entirely automated, highly efficient and with a colossal production output. Surely, there must be a way for us to harness these supply chain orientated benefits of AI without incurring all-out nuclear armageddon…?

What is AI?

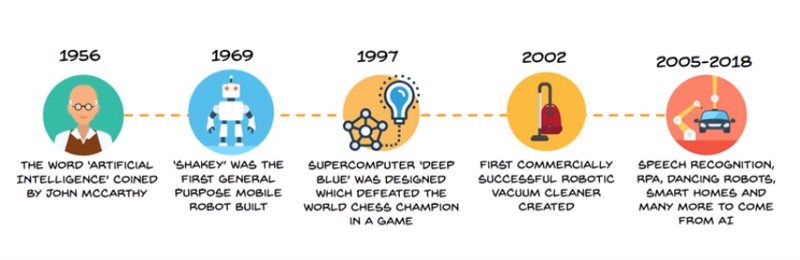

Let’s step back from the apocalyptic sci-fi depictions and come back to reality. The idea of AI has been around for decades and has evolved considerably since that time, as we can see in the graphic below.

There are perhaps as many different definitions of AI as there are potential applications for its use. The Association for the Advancement of Artificial Intelligence (https://www.aaai.org/) define AI as;

"The scientific understanding of the mechanisms underlying thought and intelligent behaviour and their embodiment in machines."

With the rapidly increasing investments in AI, the technology promises to revolutionise almost every industry and every sector within them. Gartner predicts that in 2021, AI augmentation will create $2.9 trillion dollars of business value and 6.2 billion hours of worker productivity.

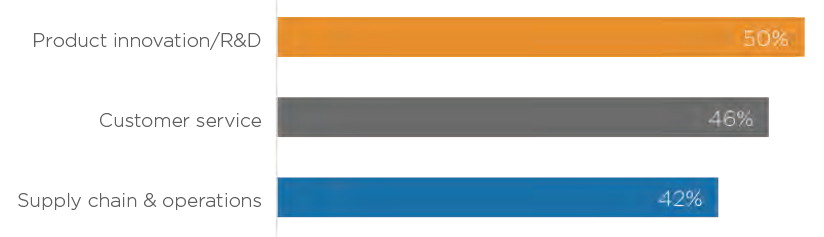

Although many areas are still under development as companies continue to explore the ways that AI can drive revenue, there are plenty of opportunities for leveraging the technology today. As Teradata explain in their “State of Artificial Intelligence for Enterprises” report, the current top three areas where businesses are driving revenue from AI are product innovation/research and development, customer service and supply chain operations.

Supply Chain Use Cases

In the same report, when asked how respondents imagined that AI could make a difference and help to drive revenue through operational excellence, the following areas were highlighted. For each of these, we’ll dive a little deeper into some of the applications that are more specific to supply chain excellence.

Automate repetitive processes and tasks that currently require human intervention (60% of Respondents)

Leveraging AI to remove the need for manual intervention in day-to-day tasks is not only one of the more obvious areas to apply the technology, but also promises some of the greatest benefits by enabling a more highly-skilled workforce to focus on tasks that cannot currently be tackled by the limited ability of AI programs. Procurement and purchasing requests could be handled without any human interaction, ensuring a steady and cost-effective flow of raw materials and finished products. Chatbots can be used to handle basic interactions with suppliers, resolving queries quickly and easily. The vast amounts of documentation required throughout supply chains can be received, classified and appropriately filed far faster and without the risk of manual errors humans are susceptible to.

Deliver new, strategic insights currently not available to business decision makers (50% of Respondents)

The ability of humans to interpret the vast amounts of data being collected in supply chains and derive useful, actionable insights from it can be limited simply by the amount of information that needs to be taken into consideration. Through machine learning, AI could be used to ensure the optimal selection of goods and suppliers in real-time based on a wide range of factors that would be beyond the ability of a person to interpret fast enough for the business to take advantage of fast-moving markets. Predictive forecasting and scenario-building tools can evaluate a huge number of variables to provide advanced insights almost instantaneously, enabling agile decision making to capitalise on the here-and-now.

Automate areas of knowledge work, reducing the need for costly human resources (49% of Respondents)

One of the more contentious areas of the application of AI is of course the reduction of expensive employees, however there is good reason for this particular avenue to be explored. While some human roles will inevitably be taken over by AI systems, those workers can certainly be re-assigned, re-trained and upskilled to add greater value to the business. Governance and compliance, such as corporate and social responsibility, sustainability and regulatory adherence, all areas based on a set of fixed parameters, are prime examples of where AI can be leveraged to reduce the costs of human resources involved while also increasing accuracy and reducing the risk of non-compliance.

Innovate faster and find new market opportunities before the competition (46% of Respondents)

In our fast-paced, consumer-driven culture, agility trumps everything. Staying one step ahead of the competition, driving new innovations and bringing them to market before anyone else can make or break a business. Through predictive modelling, scenario building and historical analysis of successes and failures, AI can provide a significant edge by identifying opportunities and predicting future trends, even instigating new creative designs.

Create efficiencies and drive down operational costs (43% of Respondents)

Given the whisker-thin margins that exist for businesses operating at every stage of supply chains, ensuring that each part operates as effectively and efficiently as possible is absolutely crucial to the long-term success of the company. AI can be used to support and optimise just-in-time manufacturing, balancing supply and demand through continuous monitoring of material availability, pricing, demand forecasting and much more. The same can be achieved for deliveries, with real-time analysis of traffic and weather conditions, enabling automated re-routing if necessary to ensure efficient delivery of goods in the shortest time possible and reducing fuel consumption, all contributing to increased margins.

Analytics is the base for AI

Whatever the use case and the intent for leveraging AI, it all begins with data. AI systems must have access to a huge range of data in order to train and build the appropriate knowledge base for each scenario. Consequently, a detailed, robust and accurate series of datasets with advanced analytical capabilities will be the foundation for any attempt to leverage AI within the supply chain for the optimisation of operational excellence.