In today’s competitive global market place, Excellence in Supply Chains is a key competitive differentiator. Hundreds of turbulent events can trigger volatility in supply markets, affecting material and service availability, resulting in higher costs. There is a need for real-time performance visibility and insight to provide a strategic advantage that enables operational agility to minimize the impact of disruptive events.

There is an increased interest in real-time supply chain support tools that address supply chain traceability, multi-level inventory optimization, demand signal repository and leveraging point-of-sale data.

Relying on traditional supply chain execution systems is becoming increasingly less viable in the context of global market fluctuations, pricing pressures and increasing customer expectations. There are also recent economic impacts such as fluctuating fuel costs, the global recession triggered by financial crisis and increased competition from low cost manufacturers. All these factors can potentially create excesses in your supply chain, but this is where analytics will help to provide a competitive edge.

What will be the impact of increasing prices on-demand? Which promotion will have the highest impact on sales? If there is limited production capacity – should production be undertaken for Product A, or more of Product B to meet our revenue and margin targets?

All businesses with supply chains devote a fair amount of time and effort to look for this competitive advantage. Due to their complexity and critical role in global commerce, supply chains plays a key part in a company’s cost structure and profitability. The use of analytics in supply chains is a great way to provide an edge over peers. Supply chains can look simple compared to other parts of a business, even though they aren’t. It is possible to dig deeper into existing data and develop more predictive insights, enabling a business to become proactive, rather than be reactive.

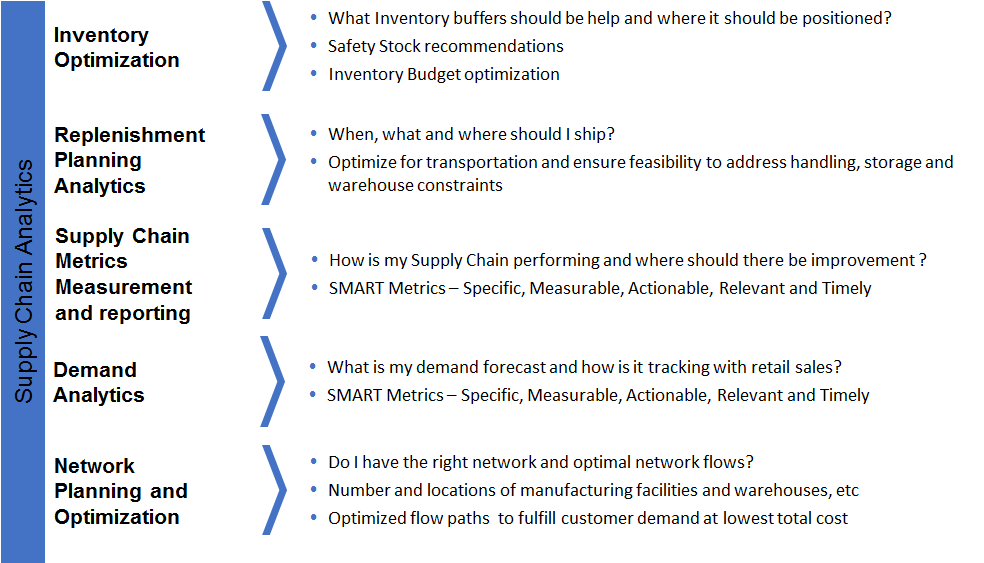

With predictive analytics, manufacturers can leverage the data within their systems, both legacy and modern, to derive real-time insights and use that information to optimise all decisions, be it operational, tactical or strategic. Industry is quickly adapting a range of analytics solutions. An overview of a few of the areas and an indication of the kinds of insights that can be undertaken is given below:

Business executives are increasingly finding that supply chain analytics are key to their company’s goals and future success. Most of them are also of the opinion that current analytics tools need to give way to more predictive analytics capabilities that help them to make quicker decision and be more responsive to volatile supply and demand needs.

At Invenio, the evolution towards leveraging supply chain analytics for customer delight, value optimisation and business growth started some time ago. For example, our Predictive Prints Demand solution is used for Newspaper Publishing Demand Management, Forecasting and Logistics. The solution helps with:

- Optimising print demands from 54,000 distributors and retailers

- Stock results based on the best utilisation of paper roles

- Savings in inventory expenses and returns costs reductions

- Rationalised and reduced expenditure on logistics

- Efficient forecasting and planning on a day-to-day basis

This data science oriented product is used for powering the entire print demands, returns, and production chains on a next-generation forecasting tool powered by SAP HANA that will accurately predict daily print needs and sales numbers using complex algorithms that take into account a diversity of factors, including weather conditions, events, historical sales and returns, competitor information, and vendor fulfilment. With the help of predictive algorithms and through instant simulation of scenarios, the sales teams and product managers will be able to respond quickly to daily newspaper market dynamics, powering the entire supply chain.

Analytics will not be a quick fix in closing existing supply chain gaps. To do this right, companies have to invest a considerable amount of resources in developing an analytics foundation before they can even run the nifty algorithms embedded in the tool. The underlying data that companies want analysed has to be accurate first, and not many companies can say that’s true for their existing data. With a high volume of data that is being generated, companies have to find and implement ways to manage and leverage data for business growth.

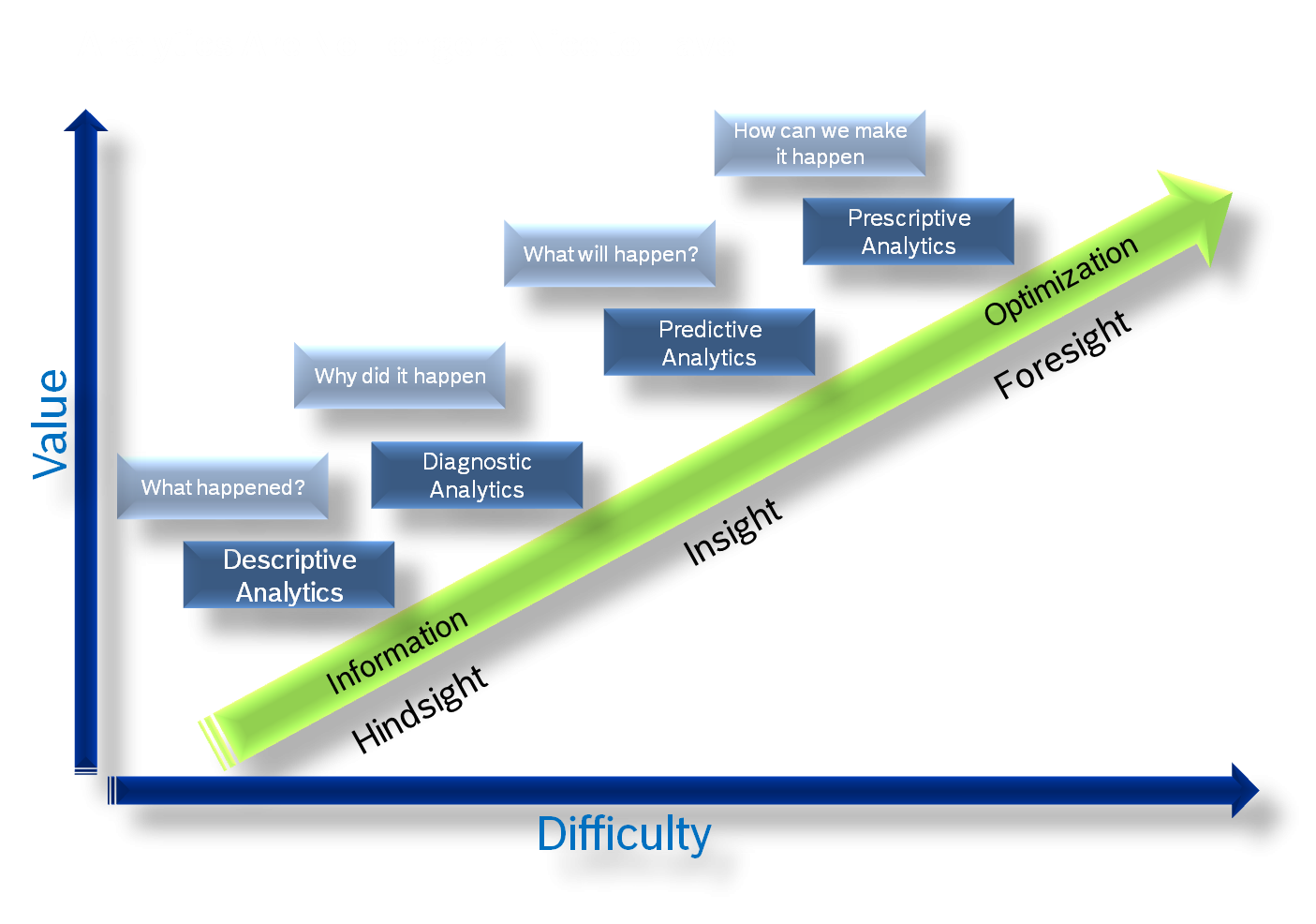

The journey towards utilizing analytics to extract maximum value as defined by Gartner is below.

As Gartner puts it, “Analytics are no longer simply a ‘Nice to have’”.

It should also be acknowledged that as a necessary foundation for moving efficiently at real-time speed, supply chain analytics is still very much at the nascent stage of development in many companies and will take time to build, however supply chain analytics promises many benefits in terms of making our supply chains leaner and more profitable.