Advanced analytical capabilities are quite simply a “must-have” for effective modern supply chain management; They are the cornerstone of successful optimisation strategies in both localised operations and across the wider supply chain network. In many respects, analytics is a fundamental capability for the further application of many of the other technologies described here.

The applications of analytics throughout the supply chain are vast and as such, must be approached with specific objectives in mind. It is crucial to define the strategic business objectives first, then to identify what insights will help drive those objectives, before defining the best analytical models to use and selecting the data sets required. These objectives can (and often should) be part of a larger goal and strategy, but without clear direction companies will run the risk of “paralysis by analysis”.

A recent report by The Hackett Group identified four main areas that are the focus of efforts to utilise analytics across the supply chain.

- Reduce Costs

- Optimise production and sourcing to reduce total landed costs

- Analyse product cost variances

- Assess the impact of commodity prices on the supply chain

- Analyse customer or channel “cost to serve”

- Improve Quality

- Identify and resolve quality defect trends and root causes

- Improve visibility to inventory across the enterprise

- Analyse product returns

- Track and analyse product traceability

- Improve Service

- Measure and analyse transportation performance

- Measure and improve distribution performance

- Analyse customer service level performance

- Optimise Inventory

- Optimise inventory levels to balance working capital investment with service levels

- Analyse demand patterns and create forecasts using internal and external data

- Analyse forecast accuracy performance

To achieve these goals, there are several accompanying areas of technological focus for organisations at every stage of the supply chain. The overall trends we see here are;

The extension of collaborative functionality to enable analytics across wider geographies, business units and partners – including enhancing core Enterprise Resource Planning (ERP) functionality and deploying virtual collaboration platforms for internal and external use.

The integration of multiple disparate systems to enhance end-to-end visibility throughout the supply chain – including platforms to better manage omnichannel planning and fulfilment, improve transaction flows with customers and suppliers, in addition to leveraging data available from machines for analytics.

The use of more sophisticated supply chain models and tools to reduce costs through process optimisation and improved service – including deploying cognitive and artificial intelligence, as well as demand sensing software to improve agility.

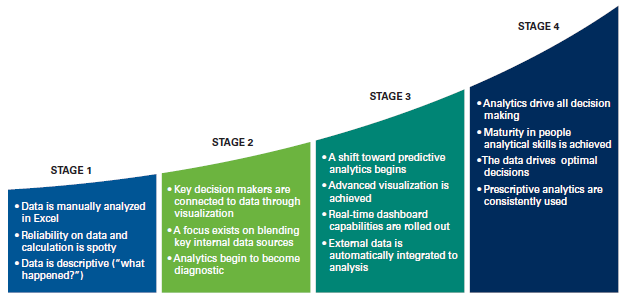

MEASURING ANALYTICS MATURITY